Sustainability

As a textile manufacturer, we are dedicated to producing our products in an environmentally and socially sustainable manner by minimizing waste, maximizing efficiency, and maintaining strong relationships with our stakeholders.

We continually evolve and enhance our processes to reduce our environmental impact while upholding the highest standards of quality and customer satisfaction.

Home / Sustainability

Our corporte social & environmental responsibility

Putting people first

At Van Heek Textiles, we are dedicated to upholding human rights by fostering a workplace rooted in equality, diversity, and respect. We prioritize fair labour practices, non-discrimination, and equal opportunities, while supporting freedom of association and investing in employee development. Our commitment extends to ensuring a safe, transparent and accountable working environment. By embedding these principles into our operations, we aim to create a supportive workplace that benefits not only our employees but also everyone connected to our business activities, positively impacting the broader communities influenced by our work.

Balancing sustainability, employee welfare and growth

We strive to balance our business objectives with environmental sustainability, employee welfare and growth. Our personnel and environmental policies are based on the principles of good cooperation and compliance with the Working Conditions Act (Arbowet), Environmental Management Act, and the Pollution of Surface Waters Act (WVOW). While compliance with regulations forms the foundation of our efforts, we are committed to going beyond the minimum requirements. This principle aligns with our core values and our commitment to sustainable and ethical business practices. It provides us with a clear framework to work towards a more sustainable future and to actively contribute to a more sustainable and equitable world.

Creating a greener tomorrow

Collaboration as the path to progress

WE support UN Global Compact

Van Heek Textiles is committed to the UN Global Compact corporate responsibility initiative and its principles in the areas of human rights, labour, the environment and anti-corruption.

Accredited work placement company

Van Heek Textiles has an official recognition as a work placement company and trains specialists for technical and textile-oriented studies. As an accredited work placement company, we are involved in shaping the future of the textile industry and are committed to passing on knowledge and experience to new generations. This way, we provide young people with the opportunity to expand their knowledge and skills for a future in the textile industry.

Proud sponsor of Oxfam Novib

Also outside our premises, we find it important to be socially involved as a company and to work towards a better world. With Oxfam Novib’s Entrepreneurs for Entrepreneurs Network we support people in developing countries in their entrepreneurial dreams. In this way, we help them to work on a better future, fight poverty, promote equality, and provide emergency aid to people in vulnerable situations—for themselves, their families, and their communities.

Supporting local businesses & initiatives

We are dedicated to fostering strong connections within our community by supporting meaningful initiatives. From the yearly Christmas market that supports local entrepreneurs to taking part in initiatives that focus on education or supporting the rich heritage of textile manufacturing in our region, we aim to create opportunities for mutual growth.

We manufacture with care

At Van Heek Textiles, we are committed to reducing water, air, and soil pollution while minimizing CO2 emissions. We carefully select and use chemicals with caution, strictly adhering to REACH regulations. By continuously learning and adopting innovative strategies, we strive to conserve energy, water, and raw materials, ensuring we remain at the forefront of social and technological advancements.

Implemented:

- Van Heek Textiles has laid impermeable floors at various production locations.

- In terms of sound, various outlets and fans have been fitted with dampers.

- PH, temperature and flow (amount of m³ waste water) are constantly measured and the amount of sludge is visually monitored.

- Waste products are collected and processed by special waste disposal companies. These companies have special permits to transport, collect and process waste products in order to prevent harmful substances from being returned to the market.

- Our factory has an advanced water purification system that enables clean water to re-enter the environment

Our products are:

- Phthalate free

- Lead-free

- Heavy metal-free

- Nontoxic

- Free of ozone-depleting chemicals

- Manufactured using aqueous coating and dyeing technology

- Our cover materials are elemental & process Chlorine-free

- Our cover materials are PVC-free

- POPs (Persistent organic pollutants) free

- CPSIA compliant

- Free of animal derivatives

The use of chemicals (e.g. dye and glue):

We carefully select our ingredients for use in our dyeing, coating, and other finishing processes. All our chemical suppliers are required to register hazardous substances imported from outside the EU, in compliance with the REACH Regulation. For every ingredient, we actively assess how substances interact with our internal processes and wastewater treatment systems, ensuring that pollutants are effectively captured and properly treated.

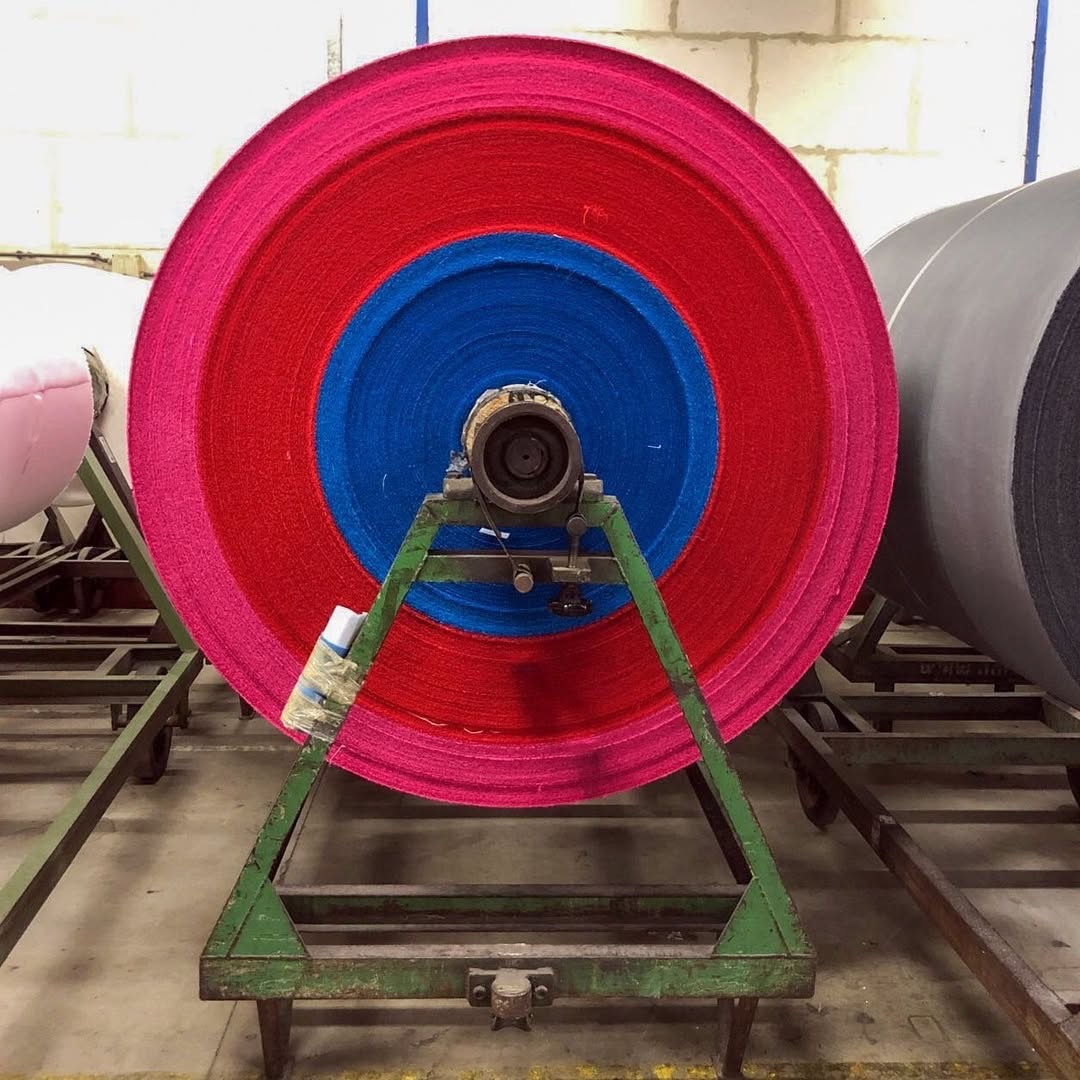

Sustainable Textile Dyeing: Cold Pad Batch Technique

For decades, we have been dyeing our natural finish cover materials following the cold pad batch technique (CPB). This method stands out for its eco-friendliness when compared to conventional dyeing methods. The process is called “cold” because it operates at or near room temperature, as opposed to traditional dyeing methods that often involve higher temperatures. As it operates at lower temperatures combined with relative low water consumption, it reduces energy consumption and environmental impact.

After the dye is mixed, the fabric is padded (rolled) through the dye liquor, ensuring an even distribution of the dye mixture onto the fabric. This padding process can be performed at room temperature, hence the term “cold pad.” So, when you purchase our natural finish cover materials, you can be assured that they were dyed using the CPB method.

Co2 emissions & Reductions

We recognize the importance of monitoring CO2 emissions and are dedicated to actively reducing our environmental impact. In 2020, we conducted our first comprehensive analysis of CO2 emissions. In 2022, we partnered with ClimatePartner and extensively reviewed our emissions, which provided us with valuable insights into our carbon footprint. This analysis has been instrumental in guiding our sustainability initiatives and implementing effective strategies to minimize emissions. Download the full report on our emissions and reductions in the download center and on the pages of ClimatePartner.

Brillianta and Brillianta Calandre are climate neutral

A comprehensive analysis and calculation of our corporate and the product carbon footprints for Brillianta and Brillianta Calandré were conducted in collaboration with ClimatePartner. The analysis and calculations have offered us valuable insights into our emissions, empowering us to implement targeted strategies for current and future emission reductions. To compensate unavoidable emissions, Van Heek Textiles financially supports climate projects aimed at forest protection. Read more about ClimatePartner certification >

Switch to Green energy

In 2021 Van Heek Textiles switched to green energy. The change from using fossil derived electricity to non-fossil (wind) derived electricity reduced the carbon footprint of Van Heek Textiles’ products with 19.8%. For the activities at the Losser factory of Van Heek this reduction is 37.9% – compared to 2019 when the zero measurement was conducted.

Switch to LENZING™ ECOVERO™ viscose

The swap of regular viscose for eco-friendly LENZING™ ECOVERO™ viscose in 2021 resulted in another 10% reduction of carbon footprint.

We source with care

Van Heek Textiles has its own weaving mill and prioritizes responsible sourcing by using recycled and natural yarns, such as such as cotton, rayon, cellulose and flax. Although the proportion of recycled yarns in our products is currently limited, we are committed to incorporating them wherever possible. We are proud to include LENZING™ ECOVERO™ fibres in our range, which are known for their eco-friendly production process.

We work mostly with European suppliers, with whom we have established long-term relationships. Being based in Europe, we are subject to stringent sustainability regulations. These regulations not only guide our practices but also set high expectations for us and our suppliers. This means our commitment to sustainability is driven not only by our values but also by legal requirements. By adhering to these standards, we ensure that our operations and those of our suppliers meet the highest sustainability criteria. This dual approach of voluntary and regulatory-driven sustainability helps us contribute positively to the environment and society.

Viscose/rayon

LENZING™ ECOVERO™

Benefits of LENZING™ ECOVERO™ fibres:

- Up to 50% lower water and CO₂ emissions impact than regular viscose.

- Derived from biodegradable wood and pulp, coming from certified and controlled resources.

- Certified with the EU Ecolabel.

The following cover materials are made from LENZING™ ECOVERO™ viscose: Brillianta, Brillianta Calandré, Coloretta, Ecojeans (partly), Saphir, Finesse, Magic, Magic Chic, Fancy Linen, Fancy Metallic, Printex

Flax

Flax fibres in our materials, Halflinnen Dark and Halflinnen Light, are certified under the Masters of Linen standard which means that the fibres are 100% EU grown and scutched. Masters of Linen stands for sustainability, European skilled jobs and social ethics. All flax under the regulation is sustainably grown – respecting the environment to achieve high quality fibres. Curious to learn more? Go to: https://www.mastersoflinen.com/

Cotton

Our cotton yarns for the materials made from 100% cotton, are originating from Africa. By buying eco-friendlier cotton from Africa we support the small farmers. They are trained to improve the production and quality of cotton and learn about responsible use of water and land. They also learn how to reduce/eliminate the use of pesticides. This system of transparency and traceability between our supplier and the purchased material also contributes to better working conditions and the elimination of child and forced labour.

Lyocell

TENCEL™ Lyocell fibres are extracted from sustainably grown wood using a unique closed loop system which recovers and reuses the solvents used, minimizing the environmental impact of production.

Recycled denim

Ecojeans consists of #hackyourjeans yarns which are made from post-consumer recycled jeans. They are collected, shredded and spun in the EU.

Recycled PET bottles

Padova Ecodure is a window covering textile made from 100% post-consumer recycled polyester with identical characteristics and hanging behaviour as traditional virgin polyester. It, however, consumes 55% less energy and 37% less CO₂ than its counterpart.

Backing paper

For our cover materials, we use solely FSC- certified 100% recycled backing paper. The paper is made of post-industrial recycled fibres, which means that every sheet of paper that is churned out is not a burden on our planet’s forests, but a reused resource. Additionally, thanks to the closed loop water circulation system the production of the paper requires less water than usual; approximately 3 litres per kilogram of paper, which is significantly less than the German industry average of 9 litres. For our standard line of cover materials, we use two variants of backing paper: 30 and 40 grams. Both variants are uncoated, acid-free and produced in Germany.

SUSTAINABILITY MARK

The sustainability mark serves as a guide for our customers, helping them choose materials crafted from environmentally friendly yarns. When applying the sustainability mark to our materials, the following criteria are considered:

- the material is made from LENZING™ ECOVERO™ viscose fibres or/and

- the material is made from recycled fibres or/and

- the material is made from sustainable cotton or/and

- the material is made from sustainable flax fibres or/and

- the material is FSC certified

We handle waste with care

Our production processes have been optimized to minimize waste and manufacture efficiently with available resources. Waste materials are separated, collected and processed by various waste disposal companies which make sure that the materials unsuitable for reuse are safely disposed with minimal impact on carbon footprint and valuable resources are being recycled and returned to the market for re-use. ♻️

We strive to protect the environment as much as possible:

- by preventing, controlling and reducing waste,

- by recycling waste material and production waste,

- by reducing water, air and soil pollution.

Collaboration with wecycled

Due to technical restrictions, during our weaving process, portion of yarn on the cones goes unused. Rather than letting it go to waste, we’ve teamed up with the WECYCLED initiative to breathe new life into the yarn and cardboard. Since 2023, cones containing leftover yarn are gathered and dispatched to sheltered workshops located near the Dutch-German border. Here, individuals with disabilities meticulously extract the yarn from the cones.

The cardboard from these cones finds its way back to the paper industry for recycling, while the remaining yarn is transformed into fibres. These fibres are then seamlessly blended with virgin cotton fibers and spun into fresh yarn, ready to embark on another weaving journey. This initiative not only reduces waste but also promotes meaningful job opportunities and supports sustainable practices within our industry.

Standards and certifications

Van Heek Textiles is aware of environmental issues and ensures strict compliance with the following standards and requirements:

- L. van Heek Textiles is FSC® certified under number PBN-COC-022077. Currently, the following qualities are FSC® certified: Brillianta, Brillianta Calandré, Dubletta, Coloretta, Saphir, Finesse, Magic, Magic Chic, Fancy Linen, Fancy Metallic, Printex, Buckram Light, Natuurlinnen, Halflinnen Dark,Brilliance, Gaas Beta and Ypsilon lined.

- The following cover materials are LENZING™ ECOVERO™ certified: Brillianta, Brillianta Calandré, Coloretta, Ecojeans, Finesse, Saphir, Fancy Linen, Fancy Metallic, Magic, Magic Chic and Printex.

- Brillianta and Brillianta Calandré are ClimatePartner certified. More information >

- EN 71-3: Safety of Toys-Part 3: Migration of certain elements. Applicable for the following materials: Brillianta, Brillianta Calandré, Saphir, Finesse, Regent, Natuur- and Halflinnen.

- REACH compliant

For more details and certificates, please visit our download centre >

We care

Van Heek Textiles actively supports and contributes to the preservation of forests and biodiversity.

- With the help of our Climate Partner Certified certification, we compensate our co2-emissions by supporting climate project in Peru. Read more about the ClimatePartner certification >

- Van Heek Textiles is arboretum Poort Bulten’s Tree Partner. Tree Partner is an initiative of Natuurmonumenten Twente.

- We have recently planted new fruit trees at our property to enhance biodiversity